Solar Panel 200w 100w ETFE PET 100W Flexible Solar Panel For 12V Battery Charger Monocrystalline Cell

Solar Panel 200w 100w ETFE PET 100W Flexible Solar Panel For 12V Battery Charger Monocrystalline Cell

Couldn't load pickup availability

⚡ Solar Panel 200w 100w ETFE PET 100W Flexible Solar Panel For 12V Battery Charger Monocrystalline Cell

Upgrade your system with our high-performance Solar Panel 200w 100w ETFE PET 100W Flexible Solar Panel For 12V Battery Charger Monocrystalline Cell. Built for reliability, efficiency and seamless integration with modern setups.

📌 Key Benefits

- ✅ High-efficiency design for superior performance

- ✅ Optimized heat dissipation and durability

- ✅ Plug-and-play compatibility for easy integration

- ✅ Ideal for industrial and residential use

📄 Technical Specifications

Solar Panel 200w 100w ETFE PET 100W Flexible Solar Panel For 12V Battery Charger Monocrystalline Cell

Specification

- is_customized: Yes

- Type: Solar Panel

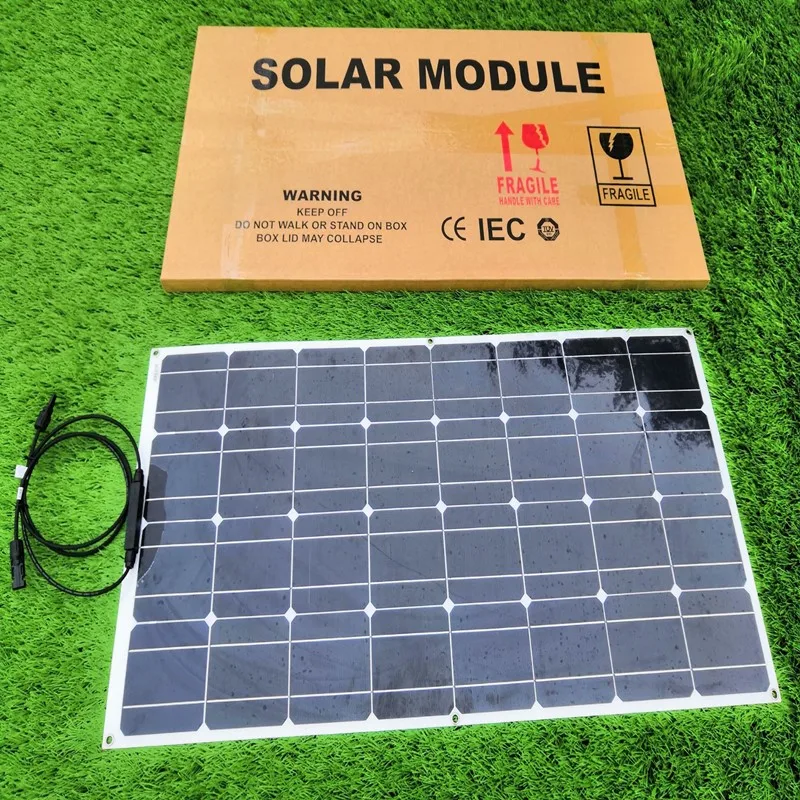

- Size: 1050X540X2.5mm

- Origin: CN(Origin)

- Number of Panels: 1

- Number of Cells: 32

- Nominal Capacity: 100w

- Model Number: JY100WF

- Max. Power: 100w

- Material: Monocrystalline Silicon

- Foldable Solar Panel: No

- Flexible solar panel: color: white

- Flexible Solar Panel: Yes

- Certification: CE

- Cell efficiency: 21.3%: Voc(V): 21.70, Isc(A): 6.10

- Brand Name: Singfo Solar

- 18v solar panel: mono solar cell

1.Mono solar cell

1) Efficient PV conversion, stable performance

2)Unique etching process can increase the short-circuit current of the solar cell

3)Advanced PECVD technology provides well-proportioned navy blue silicon nitride anti-reflection velum

4)Screen printing patterns are accurate and smoothness of the electrode is improved thus making the cell easier for welding and laser cutting

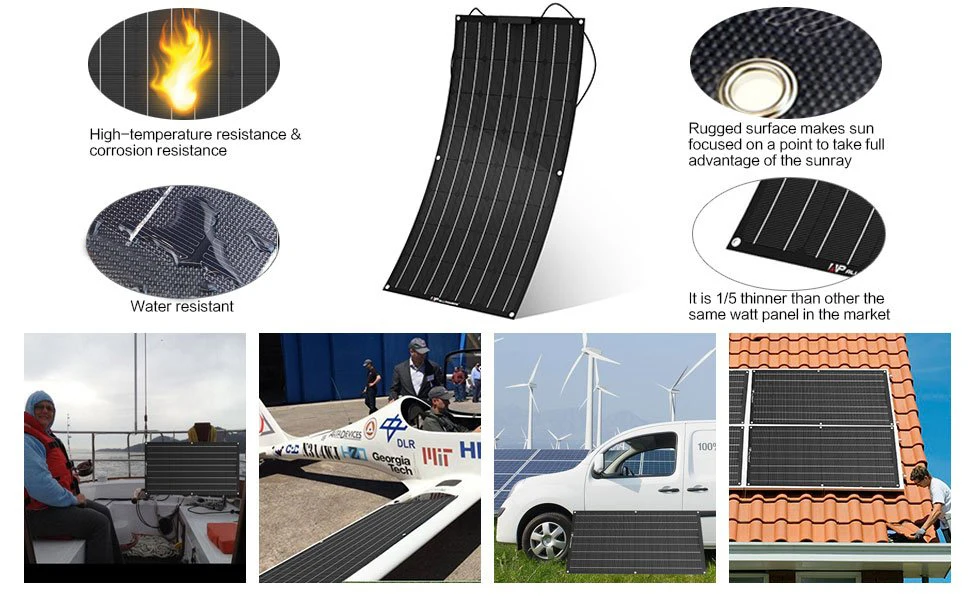

2.Front Cover ETFE FILM

1)Increase conversion efficiency by 5%

2)Enhanced surface abrasion resistance

3)High anti-fouling

4) Easy to clean

3.Backsheet TPT

The back sheet of the module is a key package material applied to the module and is mainly composed of a weather-resistant fluorine material and a PET with excellent electrical insulation properties. The service life of such products is generally designed over 25 years, and the back film is the key to ensure such a long life. The solar module back film is located on the outer layer of the module, and the solar panel back film should have high electrical insulation, high weather resistance, high adhesiveness, and low water vapor transmission rate.

4.Junction box

1)With excellent resistance to high and low temperature, fire, aging and UV resistance, it can meet the long-term use requirements under harsh outdoor environmental conditions.

2) Excellent waterproof and dustproof effect, sealed by pouring glue.

3)Compact size, compact and practical structure, suitable for thin film photovoltaic modules, widely used.

4)The connection of the bus bar and the cable are respectively welded and crimped, and the electrical performance is safe and reliable.

Packing

Normally packing: 1pc/2pcs/3pcs/10pcs/25pcs per carton

Individual packing requirement is acceptable.

5.Connector

1)Highly robustness, UV-Resistance

2)Connector adopts touch and insertion of reed with inner-knob type

3)Auto-lock equipment of male and female points enable connection more easy and reliable

4)Popular figure suits most of field installation

5)Accommodates PV cable with deferent insulation diameters

6)The maximal working current will be changed when fixed with different types of diode

Production Line

Standard Automatic Production Line

At HETECH Solar, we scour the globe in search of the most suprior materials the industry has to offer. Combined with our near fully automated manufacturing system, we offer consistently high power modules that will last a lifetime. Each material has been carefully tested to meet our best in class standards.

1.Solar cell test

New technology and most superior materials offered. combined with our automated and semi-automated manufacturing and testing system, make sure Solar cell modules high efficiency.

2.Welding

String creation by interconnecting the single photovoltaic cells, then interconnection of the strings in order to create an electrical circuit.

3.Lamination layer

Automatic pick up, rotation and positioning of the strings welding to the glass with high quality encapsulant material.

4.EL Test

EL test is able to highlight information that normally is not detectable with visual inspection, power measurement or IR testing, it is possible to identify micro cracks, degradation and shunted area on cells.

❓ Frequently Asked Questions

❓ 1 - Do you provide installation services?

❌ No, we do not. Please note that we do not provide personalized technical consulting or installation services, as customer needs vary greatly across different regions.

🌍 2 - Do you ship to my country?

Yes, we deliver worldwide. Products are shipped from suppliers located in North America, Europe, and Asia, with delivery times between 5 to 15 business days.

⏳ 3 - What is the delivery time?

Delivery time is 5 to 15 business days.

💳 4 - How can I pay?

Payments accepted via Stripe: credit card, debit card, and Apple Pay — all directly on our website.

📄 5 - Where can I find technical information?

All technical information is available on the product sales page.

❓ 6 - Can I request a quote or estimate?

🚫 No quote is necessary. You can purchase all products directly through our website with transparent pricing.

🖼 Product Images